CRS Gas filter and purifier manufacturing capabilities

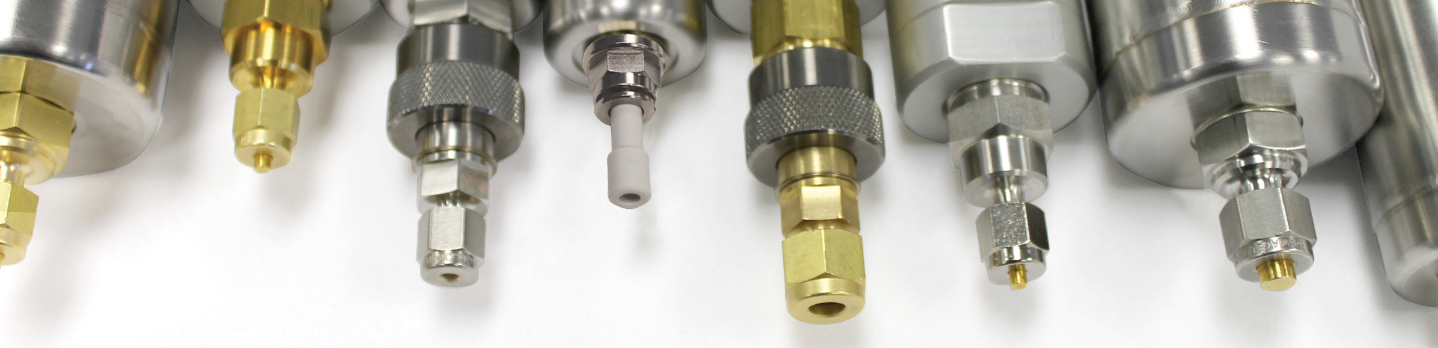

At CRS we manufacture a popular line of standard gas filters. We also custom design and build gas filters for special applications. Special requests have included the following:

- Special combinations of adsorbents to deliver required output purity levels over a range of flow rates

- Special fittings or connections for quick-connect, for push-on tube connectors, VCR fittings, or non-standard compression fittings

- Special sizes or end treatments

- CRS proprietary products include highly sensitive moisture and O2 indicators as well as very-high capacity O2 adsorbents

- CRS uses cobalt-free indicating moisture adsorbents for gas line dryers, both for high-flow low ppm applications and also to meet medium flow ppb highly demanding requirements. These adsorbents meet European requirements under REACH.

Depending on the detailed requirements, special designs and labeling can be managed for as few as 250-500 filters per year, or less if the deviations from standard products are minor.

Our gas filter products have been used in various industries such as the petroleum industry for standards in hydrocarbon type test methods, the laser and optics industry and medical industries to provide extremely clean, dry gas in critical applications. Many filters are used for additional clean up of output from gas generators, to provide clean gas for high quality welding applications, and most recently we are making arrangements to provide solutions to the semiconductor industry.

Our commitment to quality in our gas filters translates to more efficient and quality analysis, and less down time due to cartridge changes. Some of the design features can be illustrated with the Advanced Filter System (AFS), which can also be configured for special applications:

|

CRS cares:

Our attentiveness to our customers results in chromatography accessories that set new levels of value. At CRS, value is defined by quality products, technical support, guaranteed performance, and customer satisfaction. We offer an unrivaled level of expertise in our team of experienced engineers, chemists, and production employees. Whatever the need may be, we will be dedicated to each and every custom project to guarantee customer satisfaction.

Please give us a call today at 502.491.6300 with any questions you may have!