Although the use of conductive silicone tubing is common in the analysis of aerosols, several recent publications have shown that choosing the wrong conductive silicone tubing can interfere with analysis.1-3 In each of these studies, the interference was caused by volatile and semi-volatile siloxanes given off by the silicone tubing. These siloxane emissions can change aerosol particles’ surface properties, inflate particle mass leading to positive bias in mass spec analyses, and alter particles’ chemical composition leading to artifacts in downstream analyses.

Still, conductive silicone tubing is widely used because it offers two important advantages: it is flexible so connections can be made quickly in tight places and it can be used in both low- and high- temperature applications (e.g., as a sample-transfer / stand-off line in aerosol analysis of hot exhausts from automotive and aircraft engines). Another critical advantage, arising from the tubing’s conductivity, is that it helps to dissipate static and minimizes losses of sample particles to the same extent as steel tubing.1

Recently at CRS we have been working to apply our experience in manufacturing ultra-clean polymers to a variety of new applications. We find that it is possible to manufacture an ultra-low emission conductive silicone rubber tubing which retains the conductive, mechanical, and thermal properties of standard tubing – and virtually eliminates emissions.

Methods to collect emissions from silicone tubing on quartz fiber filters have been previously described.1-2, 4 We collected siloxane emissions in a procedure based on these methods, for both CRS-processed and commercially available tubing. When tubing emissions are high, the collected siloxanes are shown to change the quartz surface from being very hydrophilic to a very hydrophobic state. This change in surface energy is quite easily visualized – and is directly related to the tubing’s propensity to emit aerosol-altering siloxanes. Other parameters affecting siloxane emissions include temperature, sample residence time, and sweep gas flow rate (typical flow rates range from 5-50 L/min and sample residence times for on-line analysis can range from less than one second to less than one minute), and the vapor pressure of the siloxane impurities in the tubing (which can be elevated by increasing the temperature).

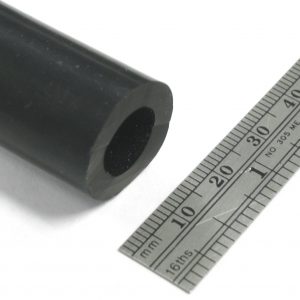

With the above considerations, conditions below were chosen to provide a challenging operational environment. Procedure: pre-heated N2 flow (70 °C, 500 mL/min) was used to collect emissions for 24-hours on 25 mm quartz fiber filter discs after passage through a) metal tubing as a control, b) 70cm of a commonly-used, commercially-available conductive silicone tubing (same nominal dimensions and conductivity as CRS tubing), and c) 70cm length of CRS conductive silicone tubing (0.44” ID, 0.75” OD, <10 Ohm·cm). After 24 hours, the quartz fiber filters were removed and affixed to a 45° angled surface. Drops of water placed on the filter surface then allowed a simple demonstration and comparison of the emissions. Figure 1: Photographic still shots from videos A, B, and C. Test A shows no siloxane collections on hydrophilic quartz filter. Test B shows a hydrophobic filter due to significant collection of siloxanes from standard silicone tubing. Test C shows minimal collection from CRS low volatile tubing. Click on videos below to watch the full 20-second clips.

It is shown in the videos below and overview of Figure 1 that emissions of CRS-processed tubing are well below the threshold required to alter the hydrophilic quartz filter. In Test A (control), we see that the quartz filter is very hydrophilic and immediately absorbs water introduced on the surface (the surface wetting properties are the same as an unused filter).

In Test B of the standard tubing, the quartz fiber filter’s surface becomes hydrophobic due to the accumulated siloxanes. The accumulated siloxane residues can be seen to cause most water droplets to simply roll off the filter surface. In the few cases where water droplets did not roll off, they remained on the surface until they slowly evaporated – the droplet at the end of Video B took over 1 hour to evaporate.

In Test C of the CRS tubing, the quartz fiber filter retains its hydrophilic surface and quickly absorbs the water droplets. The increase in hydrophobicity over an unused filter is minimal (looking very closely shows that the water droplets are absorbed only slightly slower than the control). This does indicate that some volatile siloxanes are collected, but at a much lower rate than in Test B.

When considering that emissions from CRS tubing accumulated on the downstream quartz filter for 24 hours (which is orders of magnitude longer than the < 1 minute sample residence time in on-line mass spec analysis), it seems reasonable to expect the surface wetting properties of particles to be virtually unaffected. And with such greatly reduced siloxanes, it also seems reasonable to expect more accurate real-world measurements of particle mass and chemical composition with CRS tubing than the standard tubing found to cause interference in past investigations.1-3

If you have any questions about clean conductive silicone tubing, please contact our technical team at solutions@chromres.com for further discussion.

References:

[1] Timko, M.T.; Yu, Z.; Kroll, J.; Jayne, J.T.; Worsnop, D.R.; Miake-Lye, R.C.; Onasch, T.B.; Liscinsky, D.; Kirchstetter, T.W.; Destaillats, H.; Holder, A.L.; Smith, J.D.; Wilson, K.R. Sampling Artifacts from Conductive Silicone Tubing. Aerosol Science and Technology. 2009, 43:9, 855-865.

[2] Yu, Y.; Alexander, M.L.; Perraud, V.; Bruns, E.A.; Johnson, S.N.; Ezell, M.J.; Finlayson-Pitts, B.J. Contamination from Electrically Conductive Silicone Tubing during Aerosol Chemical Analysis. Atmospheric Environment. 2009, 43, 2836-2839.

[3] Schneider, J.; Weimer, S.; Drewnick, F.; Borrmann, S.; Helas, G.; Gwaze, P.; Schmid, O.; Andreae, M.O.; Kirchner, U. Mass Spectrometric Analysis and Aerodynamic Properties of Various Types of Combustion-related Aerosol Particles. International Journal of Mass Spectrometry. 2006, 258, 37–49.

[4] Kirchstetter, T. W.; and Novakov, T. Controlled Generation of Black Carbon Particles from a Diffusion Flame and Applications in Evaluating Black Carbon Measurement Methods. Atmos. Environ. 2007, 41, 1874–1888.