Solid Phase Microextraction (SPME) is a popular way to extract and concentrate compounds from a matrix, for direct injection into a GC inlet. A tiny, retractable fiber of adsorbent material inside a needle is dipped into the solvent to collect organics, then it’s removed and drawn into the needle for protection until injection into the analytical instrument. It has many benefits: it’s quick, requires only a small amount of solvent, and it can be analyzed by either HPLC or GC. Typically it’s used with manual injection, although it can also be automated. One potential difficulty using it with GC is short injection life of the septum, and the introduction of large amounts of septum material into the inlet and the possible contamination that causes, because of the shape of the standard SPME needle.

From left to right are shown a beveled sharp-point needle, a rounded-tip autosampler needle, a standard SPME needle, and a cone-tip needle. The sharp-point needle has been in labs for decades, but today in autosampler use with GC the rounded-tip needle and the cone-tip needle are the most commonly used because they produce lower coring from the septum. The SPME needle, meanwhile, with its straight-cut tip tends to punch and tear septum material into the inlet liner. We wanted to find out what kind of GC septa would be best to use with SPME syringes to minimize potential contamination problems so we ran a few injection life tests.

Injection Life

Some septa on the market are “pre-drilled” specifically for use with SPME, which seemed a logical place to start. We also tried a leading chamfered septa (chamfered means having a guide dimple) and a chamfered / pre-pierced septa that is designed for long injection life. These are shown left-to-right above, straight from the bottle.

We followed a simple protocol: Install the test septum into a GC inlet, pierce the septum several times with the SPME syringe using an SPME syringe guide, each time extending and retracting the fiber to push out any plugged septum material, and measure for carrier gas leakage through the septum using a flow meter. After 200 piercings or failure from leakage, defined as 1 mL/min helium, the liner is photographed for visual comparison. Complete details are at the end of this blog.

Results

Photographs of the liners are shown below. All samples lasted to 200 injections with leakage below 1 mL/min, however the amount of septum material pushed into the liner varied widely.

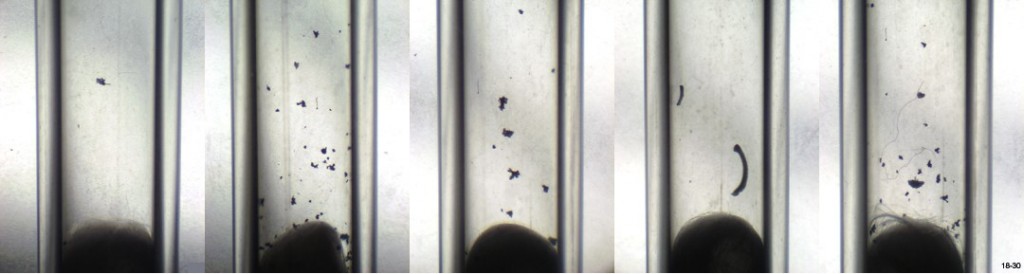

Pre-drilled for SPME

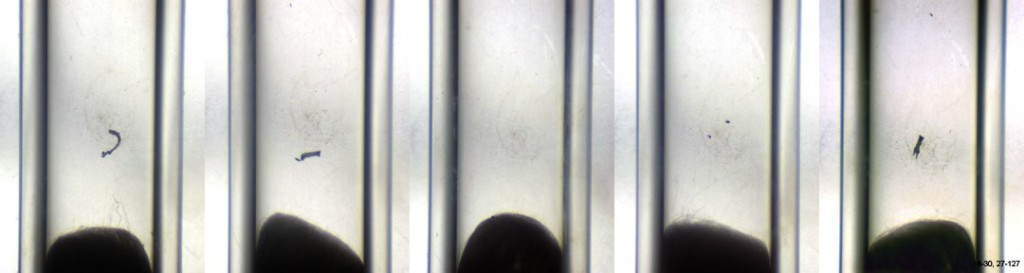

Chamfered

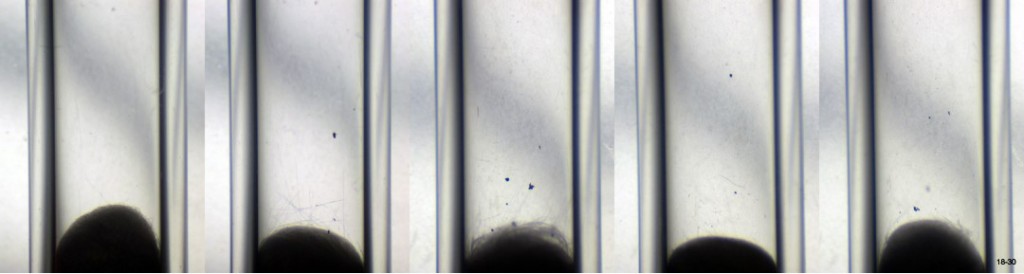

Chamfered and pre-pierced

Surprisingly, the pre-drilled septa designed for SPME performed badly in our tests. While the septa held pressure to 200 injections, the large amount of material in the liner could potentially add interfering siloxane peaks to the baseline, or even absorb analytes of interest.

Adding a chamfer to septa significantly improves performance by guiding the needle to the same location each time, reducing coring. However, without pre-piercing there is still a high risk of contamination by the SPME needle punching a septum core into the liner, presumably on the first piercing.

The chamfered / pre-pierced septa performed best over all, adding low contamination while staying leak-free at 50 psi to 200 injections, with no punched cores. Whether you’re just starting out in SPME, or you’re an experienced user seeking to reduce background contamination, this type of septa is your best bet.

Equipment:

SPME holder: Supelco #57330-U

SPME fiber assembly: Supelco #57308

SPME inlet guide: Supelco #57356-U

Adjust guard needle length to 2 – 2.5 cm

6890 GC (Agilent)

Split/Splitless Inlet 275°C, 50 psi helium

Digital Flow Check HR (Alltech) or ADM1000 (Agilent) flow meter

Procedure:

Install test septum into inlet, tighten nut 1/2 to 3/4 turn past first contact with septum, except pre-drilled septa 7/8 to 1 turn to completely compress the through-hole against leakage.

Equilibrate to temperature 10 minutes minimum.

Pierce multiple times and check for leakage at intervals. The test ends at 1.0 mL/min leak rate or 200 piercings, whichever comes first.

Test septa:

Pre-drilled, 11 mm LB-2 (Sigma-Aldrich / Supelco #23167)

Chamfered, 11 mm Advanced Green 3 (Chromatography Research Supplies #246225)

Chamfered and pre-pierced, 11 mm Marathon (Chromatography Research Supplies #239297)